The HydroServo H3e rotary direct drive servo valve (RDDV) may produce linear displacement by rotating the motor to drive the valve spool. This controls the opening and closing of the valve port, achieving accurate flow output.

The H3e valve has the most compact volume and lightest weight among similar products due to the use of metal 3D printing technology by Wuhan HydroServo Technology Co., Ltd. in designing its core hydraulic structure. Additionally, it boasts ultra-high anti-pollution ability and dynamic performance. Furthermore, it maintains excellent low-pressure performance and high reliability of the direct drive. The H3e rotary direct drive servo valve has a wide range of applications in various fields, including military, aerospace, testing, metallurgy, power sector, plastic machinery, woodworking machinery, robots, rail transit, and mobile platforms. etc. The valve’s installation bottom surface and electrical characteristics are universal, making it a popular choice in the market due to its excellent performance and competitive price.

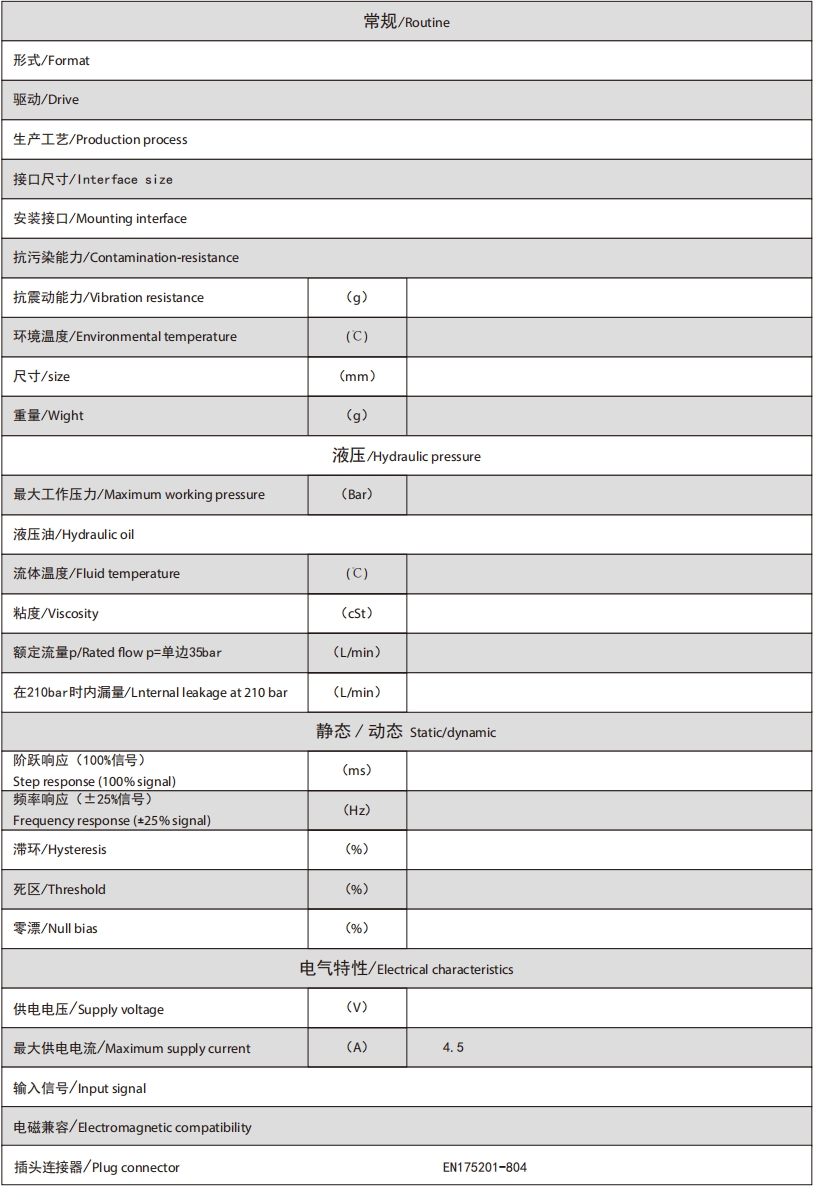

H3e Rotary Direct Drive Servo Valve:

● Small size and light weight: metal 3D printing, fluid efficiency

● Fast: (15L step <3.5ms, frequency response >170Hz)

● High accuracy: Built-in position feedback, hysteresis < 1%

● Strong anti-pollution: no nozzle, jet pipe; tiny structure, strong anti-pollution>NAS class 10

● Small internal leakage: no pilot stage, internal leakage <0.2L

A:

Can be customized.

A:

Yes you can just enter a cell phone number to log in.

A:

Direct-drive servo valves have a simpler design with fewer components and passages and no pilot stage, which reduces the risk of clogging and therefore leakage. We use digital boards that are less likely to burn out the board. It also reduces maintenance costs and extends the service life of the valve. The servo valves developed by our company can be connected to a host computer, which can accurately read the position of the valve spool and then correct the position to optimize the performance of the valve.

A:

1、Thermal power plant, for turbine hydraulic control system

2、Injection molding machine

3、Testing machine, fatigue testing machine

4、Machine tools, punching machines, lathes

5、Robot drive module

6、metallurgy on the reversible cold rolling mill, continuous rolling mill

7、 strip guiding system

8、wind power industry hydraulic pitch system

9、aircraft elevator, aileron, flight control system, automatic brake module

10、a variety of hydraulic equipment drive module

Please leave your needs, we will provide you with professional solutions